Making sure that your production process is performing to perfection is our goal. We will implement quality control machines that utilize the latest technology in sensors, lasers, and cameras. We combine this hardware with state of the art software in order to verify that everything is running smoothly in your assembly process. Our machines can verify clips, check for color, or perform many other checks and balances that your system needs. We can incorporate the correct hardware and software to make sure that no step is missed. Creating a machine made to the specifications of your part or assembly system is our main objective. Working closely with your engineers, New Technologies will take as much human error out of your quality control process as possible. Contact us today to set up a consultation. Our team is ready to work with you.

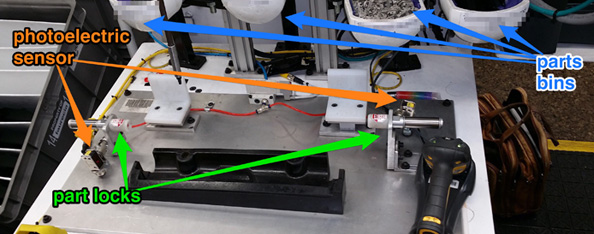

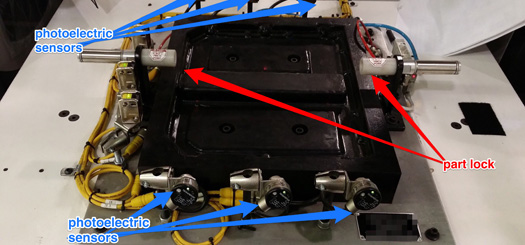

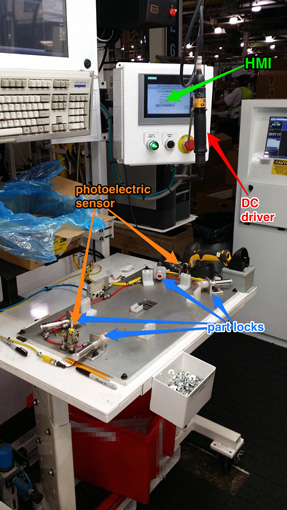

Our error proofing machines can accommodate a multitude of parts, operations, and functions. In these examples, photoelectric sensors acknowledge a part is present and activate the part locks, locking the part into position. The photoelectric sensors also recognize whether certain part details are missing or present. In both examples shown here, the DC driver is wired into an HMI (human/machine interface) unit which acknowledges the number of screw drives and also the torque of each drive. In order for the part locks to release, the HMI utilizes the sensors to recognize that the specific parts details are present. The HMI also recognizes that the DC driver has driven the correct number of screws at the correct torque. If any of these operations have not been completed satisfactorily, the locks stay in place. The HMI will display what step or part is missing from this stations process. We can incorporate a printer to print barcode labels as well. This will allow you to keep track of things such as where and when the part was made.